The American Petroleum Institute (API) and the International Organization for Standardization (ISO) have established two basic types of pipes used for exploration and production in the oil and gas industry: casing and tubing. Casing and Tubing also known as OCTG. Casing and tubing strings are the main parts of the well construction. All wells drilled for the purpose of oil or gas production (or injecting materials into underground formations) must be cased with material with sufficient strength and functionality. Well casing pipe is a pipe used in oil, gas, or water wells to protect the well walls and stabilize the wellbore.Casing pipe is used to line the drilled borehole that is being utilized for oil extraction. Similar to drill pipes, oil well casing pipe is also subjected to axial tension and therefore needs to be made from high-quality, strong steel. Casing (well pipe casing) is a large-diameter pipe fixed in the borehole using cement.Tubing is the pipe used after drilling is completed to transport crude oil and natural gas from the oil or gas reservoir to the surface.

Sizes of Casing and Tubing

Size: OD: 48.26mm-114.3mm ( Tubing)

Nominal Weight: from 9.5 lb/ft to 169 lb/ft, from 9.5 ppf to 169 ppf

Lenght: R1, R2, R3

Types of Casing and Tubing

Casing pipes are steel pipes used to support oil and gas wells, ensuring normal operation during drilling and after well completion. Each well requires multiple layers of casing depending on the drilling depth and geological conditions. Once the casing is lowered into the well, it must be cemented in place. Unlike tubing and drill pipes, casings are not reusable and are considered consumable materials. Consequently, casings account for more than 70% of the total consumption of an oil well. Casing types include seamless casing pipe(small and medium diameters), ERW casing pipe (medium diameter), casing pup joints, and casing couplings. Based on their purpose, casings are categorized as conductor casing pipe, surface casing pipe, intermediate casing pipe, and production casing pipe.

Oil well pipe casing pipes are further classified as follows:

Conductor Casing pipe: The first barrier between the surface and the underground. It helps prevent well collapse and groundwater contamination, and most importantly, provides structural support. Conductor casings are installed at the surface by drilling or driving. Their sizes range from 18 to 36 inches.

Surface Casing pipe: Primarily used for environmental protection and safety. It helps isolate freshwater zones, prevent blowouts, and supports the wellhead and blowout preventer (BOP) equipment. Therefore, surface casings must meet very high safety standards. They support the next casing string. The size can vary depending on the application, but the most common surface casing size is 13 3/8 inches.

Intermediate Casing pipe: Not required for all types of oil and gas production. If used, it is placed between the surface casing and the production casing. Sizes range from 13 3/8 to 16 inches.

Production Casing pipe: Provides structural integrity and pressure control for the hydrocarbon-bearing sections, mainly used during oil production.

Production Liner: Can be hung from the production casing pipe or one of the previous casing pipes. Liners help significantly reduce costs as they do not need to extend the entire depth of the well. They can be pre-perforated to save time and costs.

Grades of Casing and Tubing

API 5CT J55

API 5CT K55

API 5CT M65

API 5CT N80 (1,Q)

API 5CT L80 (9Cr,13Cr)

API 5CT C90

API 5CT T95

API 5CT P110

API 5CT Q125

Application of Casing and Tubing

Casing and tubing are essential oil drilling equipment with various functions such as sealing perforations, supporting wellbore walls, preventing formation collapse, and controlling well flow. Casing and tubing are widely used in petroleum exploration, extraction, and transportation. During the exploration phase, casing and tubing are used to obtain geological samples and assess the properties of underground oil reservoirs. In the extraction phase, casing supports the wellbore walls, prevents wellbore collapse, and controls well flow. In the transportation phase, tubing is used to transport oil and natural gas.

Well pipe casing is subject to external pressure from the surrounding rock and internal pressure during oil production, so it needs to withstand high axial tension. During the drilling process, good well pipe casing is very useful in the following aspects:

Fixes the drill string to prevent the collapse of unstable upper formations

Helps prevent contamination of the well area

Provides a uniform inner hole for easy installation of production equipment

Helps prevent contamination of the production area

Helps prevent liquid (oil) loss

Helps isolate the high-pressure area from the surface

Connections of Casing and Tubing

LC: Long ound thread casing

BC: Buttress thread casing

NU: Non-upset tubing

EU: External upset tubing

IJ: Integral tubing connections

Colour Code of Casing and Tubing

| Grade | Colour Code Pipe | Heat Treatment |

Characteristics and |

|

J55 |

|

Normalized, Normalized and Tempered or quenched and Tempered | Tubing & Casing for general service |

|

K55 |

|

Normalized, Normalized and Tempered or quenched and Tempered | Casing for general service |

|

N80 Type 1 |

|

Normalized or Normalized and Tempered | Tubing & Casing for general service |

|

N80 Type Q |

|

Quenched and Tempered | Tubing & Casing for general service |

|

L80 Type 1 |

|

Quenched and Tempered | Tubing & Casing with controlled yield range for sour well service |

|

L80 9 Cr |

|

Quenched and Tempered | Tubing & Casing for oil & gas wells affected by CO2 corrosion |

|

L80 13 Cr |

|

Quenched and Tempered | Tubing & Casing for oil & gas wells affected by CO2 corrosion |

|

C90 Type 1 |

|

Quenched and Tempered | Hight strength Tubing & Casing with controlled yield range for service in hydrogen sulphide environments |

|

R95 |

|

Quenched and Tempered | High strength Tubing & Casing with conntrolled yield range |

|

T95 Type 1 |

|

Quenched and Tempered | High strength Tubing & Casing with controlled yield range for service in hydrogen sulphide environments |

|

C110 |

|

Quenched and Tempered | High strength Casing with controlled yield range for service in hydrogen sulphide environments |

| P110 |  |

Quenched and Tempered | High strength Tubing & Casing for high pressure service |

| Q125 Type 1 |  |

Quenched and Tempered | Casing for deep well service |

What is casing pipe ?

What is tubing pipe ?

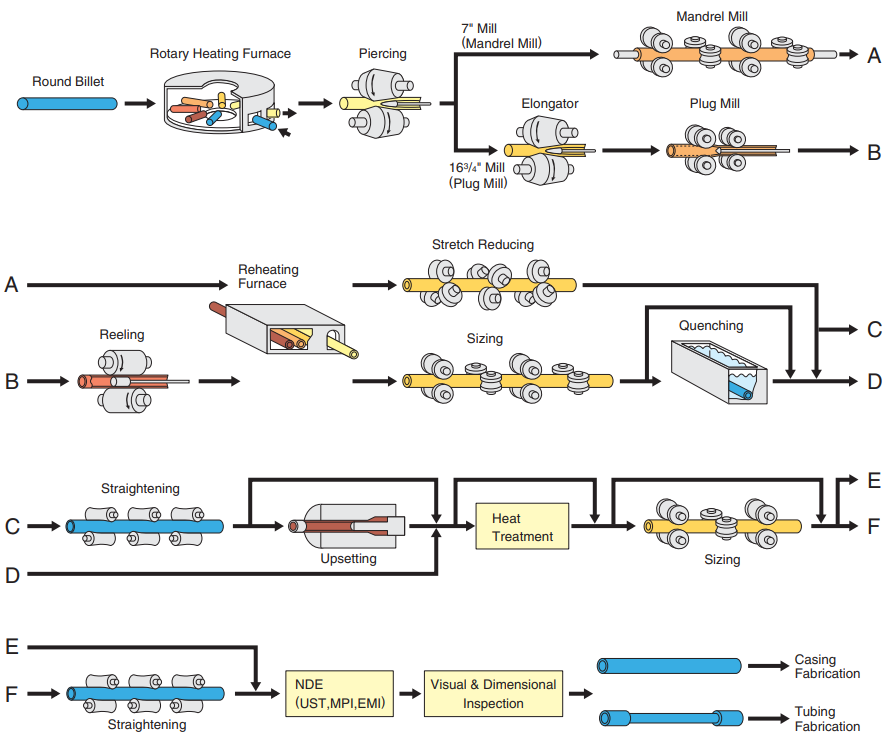

Manufacturing Process of Casing and Tubing

API Casing and Tubing Chart

Dimensions table for tubing

| DN | O. D. | Weight | W. T. | End Machining Form | ||||||||

| Steel Grade | ||||||||||||

| Inch | mm | lb/ft | kg/m | Inch | mm | H40 | J55 | L80 | N80 | C90 | P110 | |

| K55 | T95 | |||||||||||

| 4 1/2 | 4.5 | 114.3 | 9.5 | 14.14 | 0.205 | 5.21 | PS | PS | – | – | – | – |

| 10.5 | 15.63 | 0.224 | 5.69 | – | PSB | – | – | – | – | |||

| 11.6 | 17.26 | 0.25 | 6.35 | – | PSLB | PLB | PLB | PLB | PLB | |||

| 13.5 | 20.09 | 0.29 | 7.37 | – | – | PLB | PLB | PLB | PLB | |||

| 15.1 | 22.47 | 0.337 | 9.56 | – | – | – | – | – | PLB | |||

| 5 | 5 | 127 | 11.5 | 17.11 | 0.22 | 5.59 | – | PS | – | – | – | – |

| 13 | 19.35 | 0.253 | 6.43 | – | PSLB | – | – | – | – | |||

| 15 | 22.32 | 0.296 | 7.52 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 18 | 26.79 | 0.362 | 9.19 | – | – | PLB | PLB | PLBE | PLB | |||

| 21.4 | 31.85 | 0.437 | 11.1 | – | – | PLB | PLB | PLB | PLB | |||

| 23.2 | 34.53 | 0.478 | 12.14 | – | – | – | – | PLB | – | |||

| 24.1 | 35.86 | 0.5 | 12.7 | – | – | – | – | PLB | – | |||

| 5 1/2 | 5.5 | 139.7 | 14 | 20.83 | 0.244 | 6.2 | PS | PS | – | – | – | – |

| 15.5 | 23.07 | 0.275 | 6.98 | – | PSLB | – | – | – | – | |||

| 17 | 25.3 | 0.304 | 7.72 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 20 | 29.76 | 0.361 | 9.17 | – | – | PLB | PLB | PLBE | PLB | |||

| 23 | 34.23 | 0.415 | 10.54 | – | – | PLB | PLB | PLBE | PLB | |||

| 26.8 | 39.88 | 0.5 | 12.7 | – | – | – | – | – | – | |||

| 29.7 | 44.2 | 0.562 | 14.27 | – | – | – | – | – | – | |||

| 32.6 | 48.51 | 0.625 | 15.88 | – | – | – | – | – | – | |||

| 35.3 | 52.53 | 0.687 | 17.45 | – | – | – | – | – | – | |||

| 38 | 56.55 | 0.75 | 19.05 | – | – | – | – | – | – | |||

| 40.5 | 60.27 | 0.812 | 20.62 | – | – | – | – | – | – | |||

| 43.1 | 64.14 | 0.875 | 22.22 | – | – | – | – | – | – | |||

| 6 5/8 | 6.625 | 168.28 | 20 | 29.76 | 0.288 | 7.32 | PS | PSLB | – | – | – | – |

| 24 | 35.72 | 0.352 | 8.94 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 28 | 41.67 | 0.417 | 10.59 | – | – | PLB | PLB | PLBE | PLB | |||

| 32 | 47.62 | 0.475 | 12.06 | – | – | PLB | PLB | PLBE | PLB | |||

| 7 | 7 | 177.8 | 17 | 25.3 | 0.231 | 5.87 | PS | – | – | – | – | – |

| 20 | 29.76 | 0.272 | 6.91 | PS | PS | – | – | – | – | |||

| 23 | 34.23 | 0.317 | 8.05 | – | PSLB | PLB | PLB | PLBE | – | |||

| 26 | 38.69 | 0.362 | 9.19 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 29 | 43.16 | 0.408 | 10.36 | – | – | PLB | PLB | PLBE | PLB | |||

| 32 | 47.62 | 0.453 | 11.51 | – | – | PLB | PLB | PLBE | PLB | |||

| 35 | 52.09 | 0.498 | 12.65 | – | – | PLB | PLB | PLBE | PLB | |||

| 38 | 56.55 | 0.54 | 13.72 | – | – | PLB | PLB | PLBE | PLB | |||

| 42.7 | 63.54 | 0.625 | 15.88 | – | – | – | – | – | – | |||

| 46.4 | 69.05 | 0.687 | 17.45 | – | – | – | – | – | – | |||

| 50.1 | 74.56 | 0.75 | 19.05 | – | – | – | – | – | – | |||

| 53.6 | 79.77 | 0.812 | 20.62 | – | – | – | – | – | – | |||

| 57.1 | 84.97 | 0.875 | 22.22 | – | – | – | – | – | – | |||

| 7 5/8 | 7.625 | 193.68 | 24 | 35.72 | 0.3 | 7.62 | PS | – | – | – | – | – |

| 26.4 | 39.29 | 0.328 | 8.33 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 29.7 | 44.2 | 0.375 | 9.52 | – | – | PLB | PLB | PLBE | PLB | |||

| 33.7 | 50.15 | 0.43 | 10.92 | – | – | PLB | PLB | PLBE | PLB | |||

| 39 | 58.05 | 0.5 | 12.7 | – | – | PLB | PLB | PLBE | PLB | |||

| 42.8 | 63.69 | 0.562 | 14.27 | – | – | PLB | PLB | PLB | PLB | |||

| 45.3 | 67.41 | 0.595 | 15.11 | – | – | PLB | PLB | PLB | PLB | |||

| 47.1 | 70.09 | 0.625 | 15.88 | – | – | PLB | PLB | PLB | PLB | |||

| 51.2 | 76.19 | 0.687 | 17.45 | – | – | – | – | – | – | |||

| 55.3 | 80.3 | 0.75 | 19.05 | – | – | – | – | – | – | |||

| 8 5/8 | 8.625 | 219.08 | 24 | 35.72 | 0.264 | 6.71 | – | PS | – | – | – | – |

| 28 | 41.62 | 0.304 | 7.72 | PS | – | – | – | – | – | |||

| 32 | 47.62 | 0.352 | 8.94 | PS | PSLB | – | – | – | – | |||

| 36 | 53.57 | 0.4 | 10.16 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 40 | 59.53 | 0.45 | 11.43 | – | – | PLB | PLB | PLBE | PLB | |||

| 44 | 65.48 | 0.5 | 12.7 | – | – | PLB | PLB | PLBE | PLB | |||

| 49 | 72.92 | 0.557 | 14.15 | – | – | PLB | PLB | PLBE | PLB | |||

| 9 5/8 | 9.625 | 244.48 | 32.3 | 48.07 | 0.312 | 7.92 | PS | – | – | – | – | – |

| 36 | 53.57 | 0.352 | 8.94 | PS | PSLB | – | – | – | – | |||

| 40 | 59.53 | 0.395 | 10.03 | – | PSLB | PLB | PLB | PLBE | – | |||

| 43.5 | 64.73 | 0.435 | 11.05 | – | – | PLB | PLB | PLBE | PLB | |||

| 47 | 69.94 | 0.472 | 11.99 | – | – | PLB | PLB | PLBE | PLB | |||

| 53.5 | 79.62 | 0.545 | 13.84 | – | – | PLB | PLB | PLBE | PLB | |||

| 58.4 | 86.91 | 0.595 | 15.11 | – | – | PLB | PLB | PLB | PLB | |||

| 59.4 | 88.4 | 0.609 | 15.47 | – | – | – | – | – | – | |||

| 64.9 | 96.58 | 0.672 | 17.07 | – | – | – | – | – | – | |||

| 70.3 | 104.62 | 0.734 | 18.64 | – | – | – | – | – | – | |||

| 75.6 | 112.5 | 0.797 | 20.24 | – | – | – | – | – | – | |||

| 10 3/4 | 10.75 | 273.05 | 32.75 | 48.74 | 0.279 | 7.09 | PS | – | – | – | – | – |

| 40.5 | 60.27 | 0.35 | 8.89 | PS | PSB | – | – | – | – | |||

| 15.5 | 67.71 | 0.4 | 10.16 | – | PSB | – | – | – | – | |||

| 51 | 75.9 | 0.45 | 11.43 | – | PSB | PSB | PSB | PSBE | PSB | |||

| 55.5 | 82.59 | 0.495 | 12.57 | – | – | PSB | PSB | PSBE | PSB | |||

| 60.7 | 90.33 | 0.545 | 13.84 | – | – | – | – | PSBE | PSB | |||

| 65.7 | 97.77 | 0.595 | 15.11 | – | – | – | – | PSB | PSB | |||

| 73.2 | 108.93 | 0.672 | 17.07 | – | – | – | – | – | – | |||

| 79.2 | 117.86 | 0.734 | 18.64 | – | – | – | – | – | – | |||

| 85.3 | 126.94 | 0.797 | 20.24 | – | – | – | – | – | – | |||

| 11 3/4 | 11.75 | 42 | 62.5 | 0.333 | 8.46 | PS | – | – | – | – | – | |

| 47 | 69.94 | 0.375 | 20.24 | – | – | – | – | – | – | |||

| 54 | 80.36 | 0.435 | 8.46 | – | – | – | – | – | – | |||

| 60 | 89.29 | 0.489 | 9.53 | – | – | – | – | – | – | |||

| 65 | 96.73 | 0.534 | 11.05 | – | – | – | – | – | – | |||

| 71 | 105.66 | 0.582 | 14.42 | – | – | – | – | – | – | |||

| 13 3/8 | 13.375 | 339.73 | 48 | 71.43 | 0.33 | 8.38 | PS | – | – | – | – | – |

| 54.5 | 81.1 | 0.38 | 9.65 | – | PSB | – | – | – | – | |||

| 61 | 90.78 | 0.43 | 10.92 | – | PSB | – | – | – | – | |||

| 68 | 101.19 | 0.48 | 12.19 | – | PSB | PSB | PSB | PSB | PSB | |||

| 72 | 107.15 | 0.514 | 13.06 | – | – | PSB | PSB | PSB | PSB | |||

| 16 | 16 | 406.4 | 65 | 96.73 | 0.375 | 9.53 | PS | – | – | – | – | – |

| 75 | 111.61 | 0.438 | 11.13 | – | PSB | – | – | – | – | |||

| 84 | 125.01 | 0.495 | 12.57 | – | PSB | – | – | – | – | |||

| 109 | 162.21 | 0.656 | 16.66 | – | P | P | P | – | P | |||

| 18 5/8 | 18.625 | 473.08 | 87.5 | 130.21 | 0.435 | 11.05 | PS | PSB | – | – | – | – |

| 20 | 20 | 508 | 94 | 139.89 | 0.438 | 11.13 | PSL | PSLB | – | – | – | – |

| 106.5 | 158.49 | 0.5 | 12.7 | – | PSLB | – | – | – | – | |||

| 133 | 197.93 | 0.635 | 16.13 | – | PSLB | – | – | – | – | |||

| P——Plain;S——Short-thread;L——Long-thread;B——Buttress thread;E——Extreme thread | ||||||||||||

Dimensions table for casing

| DN | O. D. | Weight | W. T. | End Machining Form | ||||||||

| Steel Grade | ||||||||||||

| Inch | mm | lb/ft | kg/m | Inch | mm | H40 | J55 | L80 | N80 | C90 | P110 | |

| K55 | T95 | |||||||||||

| 4 1/2 | 4.5 | 114.3 | 9.5 | 14.14 | 0.205 | 5.21 | PS | PS | – | – | – | – |

| 10.5 | 15.63 | 0.224 | 5.69 | – | PSB | – | – | – | – | |||

| 11.6 | 17.26 | 0.25 | 6.35 | – | PSLB | PLB | PLB | PLB | PLB | |||

| 13.5 | 20.09 | 0.29 | 7.37 | – | – | PLB | PLB | PLB | PLB | |||

| 15.1 | 22.47 | 0.337 | 9.56 | – | – | – | – | – | PLB | |||

| 5 | 5 | 127 | 11.5 | 17.11 | 0.22 | 5.59 | – | PS | – | – | – | – |

| 13 | 19.35 | 0.253 | 6.43 | – | PSLB | – | – | – | – | |||

| 15 | 22.32 | 0.296 | 7.52 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 18 | 26.79 | 0.362 | 9.19 | – | – | PLB | PLB | PLBE | PLB | |||

| 21.4 | 31.85 | 0.437 | 11.1 | – | – | PLB | PLB | PLB | PLB | |||

| 23.2 | 34.53 | 0.478 | 12.14 | – | – | – | – | PLB | – | |||

| 24.1 | 35.86 | 0.5 | 12.7 | – | – | – | – | PLB | – | |||

| 5 1/2 | 5.5 | 139.7 | 14 | 20.83 | 0.244 | 6.2 | PS | PS | – | – | – | – |

| 15.5 | 23.07 | 0.275 | 6.98 | – | PSLB | – | – | – | – | |||

| 17 | 25.3 | 0.304 | 7.72 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 20 | 29.76 | 0.361 | 9.17 | – | – | PLB | PLB | PLBE | PLB | |||

| 23 | 34.23 | 0.415 | 10.54 | – | – | PLB | PLB | PLBE | PLB | |||

| 26.8 | 39.88 | 0.5 | 12.7 | – | – | – | – | – | – | |||

| 29.7 | 44.2 | 0.562 | 14.27 | – | – | – | – | – | – | |||

| 32.6 | 48.51 | 0.625 | 15.88 | – | – | – | – | – | – | |||

| 35.3 | 52.53 | 0.687 | 17.45 | – | – | – | – | – | – | |||

| 38 | 56.55 | 0.75 | 19.05 | – | – | – | – | – | – | |||

| 40.5 | 60.27 | 0.812 | 20.62 | – | – | – | – | – | – | |||

| 43.1 | 64.14 | 0.875 | 22.22 | – | – | – | – | – | – | |||

| 6 5/8 | 6.625 | 168.28 | 20 | 29.76 | 0.288 | 7.32 | PS | PSLB | – | – | – | – |

| 24 | 35.72 | 0.352 | 8.94 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 28 | 41.67 | 0.417 | 10.59 | – | – | PLB | PLB | PLBE | PLB | |||

| 32 | 47.62 | 0.475 | 12.06 | – | – | PLB | PLB | PLBE | PLB | |||

| 7 | 7 | 177.8 | 17 | 25.3 | 0.231 | 5.87 | PS | – | – | – | – | – |

| 20 | 29.76 | 0.272 | 6.91 | PS | PS | – | – | – | – | |||

| 23 | 34.23 | 0.317 | 8.05 | – | PSLB | PLB | PLB | PLBE | – | |||

| 26 | 38.69 | 0.362 | 9.19 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 29 | 43.16 | 0.408 | 10.36 | – | – | PLB | PLB | PLBE | PLB | |||

| 32 | 47.62 | 0.453 | 11.51 | – | – | PLB | PLB | PLBE | PLB | |||

| 35 | 52.09 | 0.498 | 12.65 | – | – | PLB | PLB | PLBE | PLB | |||

| 38 | 56.55 | 0.54 | 13.72 | – | – | PLB | PLB | PLBE | PLB | |||

| 42.7 | 63.54 | 0.625 | 15.88 | – | – | – | – | – | – | |||

| 46.4 | 69.05 | 0.687 | 17.45 | – | – | – | – | – | – | |||

| 50.1 | 74.56 | 0.75 | 19.05 | – | – | – | – | – | – | |||

| 53.6 | 79.77 | 0.812 | 20.62 | – | – | – | – | – | – | |||

| 57.1 | 84.97 | 0.875 | 22.22 | – | – | – | – | – | – | |||

| 7 5/8 | 7.625 | 193.68 | 24 | 35.72 | 0.3 | 7.62 | PS | – | – | – | – | – |

| 26.4 | 39.29 | 0.328 | 8.33 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 29.7 | 44.2 | 0.375 | 9.52 | – | – | PLB | PLB | PLBE | PLB | |||

| 33.7 | 50.15 | 0.43 | 10.92 | – | – | PLB | PLB | PLBE | PLB | |||

| 39 | 58.05 | 0.5 | 12.7 | – | – | PLB | PLB | PLBE | PLB | |||

| 42.8 | 63.69 | 0.562 | 14.27 | – | – | PLB | PLB | PLB | PLB | |||

| 45.3 | 67.41 | 0.595 | 15.11 | – | – | PLB | PLB | PLB | PLB | |||

| 47.1 | 70.09 | 0.625 | 15.88 | – | – | PLB | PLB | PLB | PLB | |||

| 51.2 | 76.19 | 0.687 | 17.45 | – | – | – | – | – | – | |||

| 55.3 | 80.3 | 0.75 | 19.05 | – | – | – | – | – | – | |||

| 8 5/8 | 8.625 | 219.08 | 24 | 35.72 | 0.264 | 6.71 | – | PS | – | – | – | – |

| 28 | 41.62 | 0.304 | 7.72 | PS | – | – | – | – | – | |||

| 32 | 47.62 | 0.352 | 8.94 | PS | PSLB | – | – | – | – | |||

| 36 | 53.57 | 0.4 | 10.16 | – | PSLB | PLB | PLB | PLBE | PLB | |||

| 40 | 59.53 | 0.45 | 11.43 | – | – | PLB | PLB | PLBE | PLB | |||

| 44 | 65.48 | 0.5 | 12.7 | – | – | PLB | PLB | PLBE | PLB | |||

| 49 | 72.92 | 0.557 | 14.15 | – | – | PLB | PLB | PLBE | PLB | |||

| 9 5/8 | 9.625 | 244.48 | 32.3 | 48.07 | 0.312 | 7.92 | PS | – | – | – | – | – |

| 36 | 53.57 | 0.352 | 8.94 | PS | PSLB | – | – | – | – | |||

| 40 | 59.53 | 0.395 | 10.03 | – | PSLB | PLB | PLB | PLBE | – | |||

| 43.5 | 64.73 | 0.435 | 11.05 | – | – | PLB | PLB | PLBE | PLB | |||

| 47 | 69.94 | 0.472 | 11.99 | – | – | PLB | PLB | PLBE | PLB | |||

| 53.5 | 79.62 | 0.545 | 13.84 | – | – | PLB | PLB | PLBE | PLB | |||

| 58.4 | 86.91 | 0.595 | 15.11 | – | – | PLB | PLB | PLB | PLB | |||

| 59.4 | 88.4 | 0.609 | 15.47 | – | – | – | – | – | – | |||

| 64.9 | 96.58 | 0.672 | 17.07 | – | – | – | – | – | – | |||

| 70.3 | 104.62 | 0.734 | 18.64 | – | – | – | – | – | – | |||

| 75.6 | 112.5 | 0.797 | 20.24 | – | – | – | – | – | – | |||

| 10 3/4 | 10.75 | 273.05 | 32.75 | 48.74 | 0.279 | 7.09 | PS | – | – | – | – | – |

| 40.5 | 60.27 | 0.35 | 8.89 | PS | PSB | – | – | – | – | |||

| 15.5 | 67.71 | 0.4 | 10.16 | – | PSB | – | – | – | – | |||

| 51 | 75.9 | 0.45 | 11.43 | – | PSB | PSB | PSB | PSBE | PSB | |||

| 55.5 | 82.59 | 0.495 | 12.57 | – | – | PSB | PSB | PSBE | PSB | |||

| 60.7 | 90.33 | 0.545 | 13.84 | – | – | – | – | PSBE | PSB | |||

| 65.7 | 97.77 | 0.595 | 15.11 | – | – | – | – | PSB | PSB | |||

| 73.2 | 108.93 | 0.672 | 17.07 | – | – | – | – | – | – | |||

| 79.2 | 117.86 | 0.734 | 18.64 | – | – | – | – | – | – | |||

| 85.3 | 126.94 | 0.797 | 20.24 | – | – | – | – | – | – | |||

| 11 3/4 | 11.75 | 42 | 62.5 | 0.333 | 8.46 | PS | – | – | – | – | – | |

| 47 | 69.94 | 0.375 | 20.24 | – | – | – | – | – | – | |||

| 54 | 80.36 | 0.435 | 8.46 | – | – | – | – | – | – | |||

| 60 | 89.29 | 0.489 | 9.53 | – | – | – | – | – | – | |||

| 65 | 96.73 | 0.534 | 11.05 | – | – | – | – | – | – | |||

| 71 | 105.66 | 0.582 | 14.42 | – | – | – | – | – | – | |||

| 13 3/8 | 13.375 | 339.73 | 48 | 71.43 | 0.33 | 8.38 | PS | – | – | – | – | – |

| 54.5 | 81.1 | 0.38 | 9.65 | – | PSB | – | – | – | – | |||

| 61 | 90.78 | 0.43 | 10.92 | – | PSB | – | – | – | – | |||

| 68 | 101.19 | 0.48 | 12.19 | – | PSB | PSB | PSB | PSB | PSB | |||

| 72 | 107.15 | 0.514 | 13.06 | – | – | PSB | PSB | PSB | PSB | |||

| 16 | 16 | 406.4 | 65 | 96.73 | 0.375 | 9.53 | PS | – | – | – | – | – |

| 75 | 111.61 | 0.438 | 11.13 | – | PSB | – | – | – | – | |||

| 84 | 125.01 | 0.495 | 12.57 | – | PSB | – | – | – | – | |||

| 109 | 162.21 | 0.656 | 16.66 | – | P | P | P | – | P | |||

| 18 5/8 | 18.625 | 473.08 | 87.5 | 130.21 | 0.435 | 11.05 | PS | PSB | – | – | – | – |

| 20 | 20 | 508 | 94 | 139.89 | 0.438 | 11.13 | PSL | PSLB | – | – | – | – |

| 106.5 | 158.49 | 0.5 | 12.7 | – | PSLB | – | – | – | – | |||

| 133 | 197.93 | 0.635 | 16.13 | – | PSLB | – | – | – | – | |||

|

P——Plain;S——Short-thread;L——Long-thread;B——Buttress thread;E——Extreme thread

|

||||||||||||